Electric motor: how to extend the service life

Today electrical equipment has become not only popular, it has entered all spheres of everyday life and industry and has firmly established itself everywhere. The electric motor has become an integral part of all, without exception, areas ...

Today electrical equipment has become not only popular, it has entered all spheres of everyday life and industry and has firmly established itself everywhere. The electric motor has become an integral part of all, without exception, areas ...

... construction, transport, food, agricultural and others - everywhere it is important and needed.

It is clear that each copy, as well as everything in this world, has its own service life. Yes, electric motors are short-lived, but you can increase the time of their use if you perform simple manipulations and adhere to the basic rules. So why not take advantage of this?

Since all electric motors are divided into two types (brush and rotary), their care is different. The essence is in the design. Brushes consist of an armature with a collector, a stator with pole coils, as well as brushes and brush holders. Rotary - rotor and stator with phase coils.

Caring for brush motors

1. We control the brushes. Their complete wear must not be allowed! Have a repair kit always on hand. If there is such a moment that the electric motor is disassembled for any reason, be sure to use this and check the brushes. Their wear should not be too strong, and movement in the brush holders should be free. Also, as the brush wipes off the collector plates, you need to evenly stretch the spring that presses it against the armature collector.

2. We monitor the bearings at the armature, do not allow their severe wear. Even a small backlash is a reason for bearing replacement. And do not forget: the lubrication must be constant!

3. Forget about sandpaper and small file. It is forbidden to clean the collector plates with them! To "extend" (not to allow the plates to join together) is yes, but not to clean.

Rotary Motors Care

1. We monitor the state of lubrication of the bearings on the rotor. Replacement is required if there is the slightest backlash. If it is not done, the load on the electric motor will increase, the wires in the winding will heat up, and the insulation on them will be damaged. As a result - turn-to-turn closure or short circuit to the motor housing.

2. We replace capacitors at the end of their service life. Not all electric motors have capacitors, but which are present, they need periodic replacement.

3. If we are talking about 380 V motors, we control the voltage between phases, between phases and zero. Phase imbalance, that is, the presence of different voltages, must not be allowed, otherwise the breakdown of the electric motor cannot be avoided!

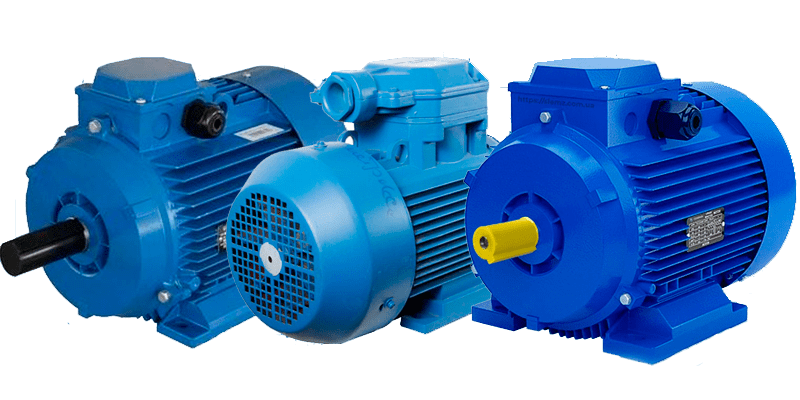

Buy a quality electric motor

Undoubtedly, you need to know and be able to take care of electrical equipment. But it is equally important to buy an initially high-quality electric motor. Exactly these from the best manufacturers are offered by the company "Expomotors" - an enterprise with many years of experience and a high level of each unit of goods.

Turning to the experts of "Expomotors", you can count on advisory support, quality assurance and comfortable cooperation. So, if you need to buy an electric motor, call! You can't find a better supplier!